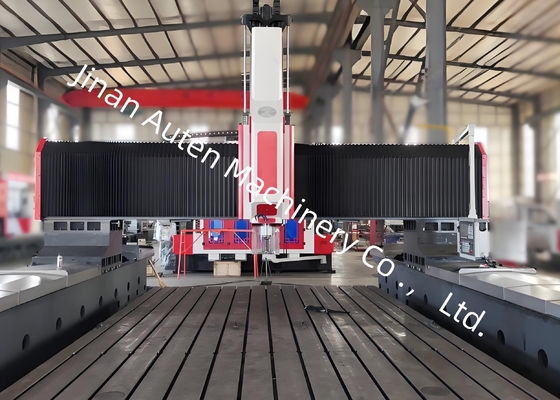

100mm Gantry Height High-Performance CNC Plate Drilling Machine 22kw Servo Spindle Motor Power

Equipment Application:

This Machinery CNC Gantry Drilling and Milling Machine Series is primarily used for drilling, chamfering, tapping, milling, and boring operations on plate/structural component parts. It efficiently drills holes in workpieces such as flanges, discs, rings, and plates with thicknesses within the effective range. It can drill through holes and blind holes on both single-material parts and composite materials. The machine tool's processing is digitally controlled, making operation extremely convenient. It enables automated, high-precision, multi-variety, and large-scale production.

Equipment Structure:

This equipment mainly consists of a cast bed workbench, a mobile gantry, a mobile saddle, a drilling and milling power head, an automatic lubrication device and protective device, a circulating cooling device, a digital control system, and an electrical system. Rolling guideways provide support and guidance, while precision screw drives ensure high positioning accuracy and repeatability.

1. Bed and worktable:

The bed and worktable are made of gray iron (HT250) as integral castings, undergo secondary annealing and aging treatment, and are precision-machined to ensure excellent dynamic and static rigidity without deformation. The worktable surface features precision-machined T-slots arranged in a rational layout for clamping workpieces. The bed base is equipped with two high-precision linear guideways on each side, ensuring uniform force distribution on the guideway slides, significantly enhancing the machine tool's rigidity and resistance to tensile and compressive forces. The drive system employs AC servo motors and precision ball screw pairs for dual-side drive, enabling the gantry to move along the Y-axis. Adjustable bolts are distributed on the bed base, allowing for convenient adjustment of the bed and worktable's horizontal level.

2. Mobile gantry:

The mobile gantry is made of gray iron (HT250) and has two ultra-high load-bearing rolling linear guideways installed on the front side of the gantry. A set of precision ball screw pairs and a servo motor enable the power head slide to move in the X-axis direction. Drilling power heads are installed on the power head slide.

3. Moving saddle:

The moving saddle is a precision cast iron structural component. It is equipped with two high-load-bearing CNC linear guideways, a set of precision ball screw assemblies, and a high-precision planetary reducer connected to a servo motor. It also features a nitrogen-balanced cylinder. balancing the weight of the power head to reduce the load on the ball screw and extend its service life. It drives the drilling power head to move in the Z-axis direction, enabling functions such as rapid feed, working feed, rapid retraction, and stop. It also features automatic chip breaking, chip removal, and pause functions.

Technical Parameter Table:

| Name |

Item |

Parameter Value |

| Maximum workpiece processing dimensions |

Length × Width (mm) |

3000*2500 |

| Gantry height (mm) |

1000 (can also be determined based on the foundation) |

| Workbench |

T-slot width (mm) |

28 |

| Vertical ram-type drilling power head |

Quantity (unit) |

1 |

| Spindle taper hole |

BT50-190 |

| Drilling diameter (ordinary carbon steel) (mm) |

Φ1-Φ90 |

| Tapping diameter (mm) |

M3-M30 |

| Spindle speed (r/min) |

30~3000 |

| Servo spindle motor power (kW) |

22kw |

| Distance from spindle lower end face to worktable (mm) |

200-1200 |

| Power head lateral movement (X-axis) |

Maximum lateral travel (mm) |

2500 |

| Lateral movement speed (m/min) |

0~8 |

| Lateral movement servo motor power (kW) |

4.2*1 |

| Gantry longitudinal movement (Y-axis) |

Maximum feed travel (mm) |

3000 |

| Feed movement speed (m/min) |

0~8 |

| Feed servo motor power (kW) |

4.2*2 |

| Vertical slide feed motion (Z axis) |

Maximum travel (mm) |

1000 |

| Movement speed (m/min) |

0~6 |

| Servo motor power (kW) |

3.6*1 (brake) |

| Three-axis positioning accuracy |

X/Y/Z/A/B/C |

±0.015/1000mm |

| Three-axis repeat positioning accuracy |

X/Y/Z/A/B/C |

±0.01/1000mm |

| External dimensions |

8200*6500*5000mm |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!