Hot Sale Automatric High speed CNC H beam Drilling Machine Line for Steel Structure Model BHD1250C

Application industry:

This machine tool is mainly used for drilling of H-shaped steel. The machine tool uses three high-speed precision drilling spindles to drill the workpiece. It has the characteristics of high machining accuracy and convenient operation. It is an indispensable high-efficiency equipment in the steel structure industry and is widely used in construction, bridges, tower masts and grids. And other industries.

Machine structure:

1.This machine tool is mainly composed of main machine body, cnc feeding system, material conveyor, electrical system, hydraulic system, cooling system, lubrication system, waste box and other parts. The machine tool adopts a fixed bed structure and a movable workpiece structure, which is suitable for the processing of large H-shaped steel, is convenient for continuous production, and has a high degree of automation.

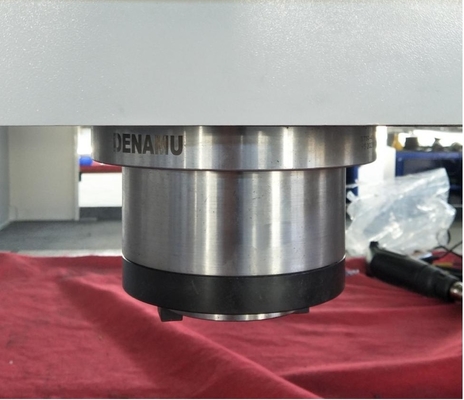

2.The drilling machine body is composed of bed, CNC sliding table components, supporting device, upper pressing device, side pressing device, detection device and so on. The parts of the numerical control sliding table are the fixed side, the moving side and the upper unit numerical control sliding table. The sliding table components are composed of a sliding plate, a sliding table seat, a headstock, a high-speed mechanical spindle, a tool cylinder, a frequency conversion motor, a servo motor, a linear guide, a lead screw, etc., which are used for drilling of H-shaped steel.

3.The CNC feeding system is composed of bracket, gear, rack, servo motor, reducer and manipulator. The servo motor drives the manipulator to drive the H-shaped steel to move in the X direction to feed the H-shaped steel, which can realize the precise positioning of the workpiece.

Specifications:

| H beam parameter |

Max. Size Width x Height |

1250×600mm |

| Min. Size Width x Height |

200×75mm |

| Max. Beam Length |

12000mm |

| Main spindle |

Qty. |

3 |

| Model |

BT40 |

| Motor power |

3x11 kW |

| Spindle speed |

200~3000 r/min |

| Max. Hole diameter |

φ40 mm |

| Motor power |

Feed servo motor power |

2x3 kW |

| Positioning servo motor power |

2x3 kW |

| Processing Accuracy |

Hole distance deviation |

Two holes within 1 meter |

±0.5 |

| The allowable deviation value increases by ±0.2mm for every additional 1 meter of the hole distance, and the maximum does not exceed ±2mm |

| End margin deviation |

±1.0 mm |

| Hydraulic system |

Hydraulic pump pressure |

7 MPa |

| Oil pump motor power |

7kW |

| Electrical System |

Control method |

PLC |

| Number of CNC axes |

7 |

| Overall size (L x W x H) |

32000x6200x4000 |

| Weight of main machine |

About 15000kg |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!