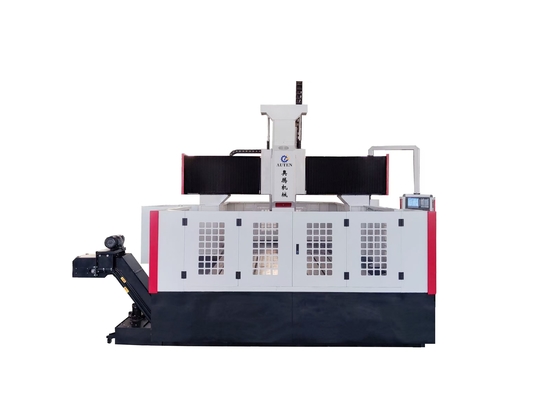

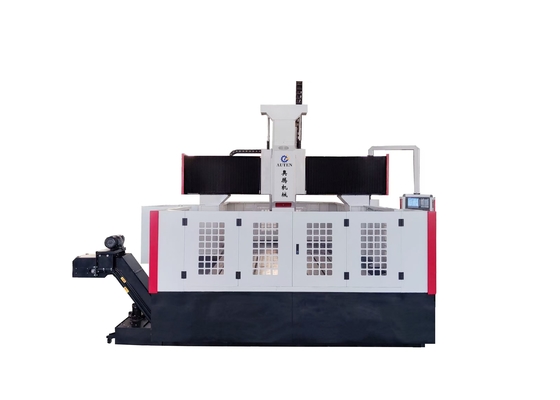

Application:

The CNC gantry drilling and milling machine is primarily engineered for performing drilling, chamfering, tapping, and milling operations on plate/structural components—including flanges, discs, rings, and plates—within its effective processing range, regardless of their thickness. It is capable of drilling both through holes and blind holes in single-material parts and composite materials alike. The machining process is digitally controlled, ensuring highly user-friendly operation, and it supports automated production with high precision, adaptability to multiple product varieties, and scalability for mass manufacturing.

Equipment Structure:

The equipment is primarily composed of a bed worktable, movable gantry, movable sliding saddle, drilling and milling power head, automatic lubrication system, protective mechanism, circulating cooling device, numerical control system, and electrical system. Supported and guided by rolling guide pairs, and driven by precision lead screw pairs, the machine tool boasts high positioning accuracy and repeat positioning accuracy.

Machine Bed and Workbench:

The machine bed undergoes welding, followed by annealing and precision machining, ensuring exceptional dynamic and static rigidity with permanent dimensional stability. Two high-precision linear guides are mounted on both sides of the bed base, enabling uniform force distribution across the guide sliders and significantly enhancing the machine’s rigidity, tensile strength, and compressive resistance. The drive system employs AC servo motors paired with precision ball screw assemblies for dual-sided drive, facilitating the gantry’s movement along the Y-axis. Additionally, the workbench is integrated with a hydraulic cylinder clamping system for secure workpiece fixation.

Mobile Gantry:

The mobile gantry is constructed from gray iron (HT250) castings, with two ultra-high load-bearing rolling linear guides mounted on its front face. A set of precision ball screws, in conjunction with a servo motor, enables the power head slide plate to traverse along the X-axis, and the drilling power head is affixed to this slide plate. The gantry’s movement is facilitated by a servo motor, which drives the rotation of the ball screw nut on the ball screw via a precision coupling to achieve smooth and precise motion.

Specifications:

| Workpiece size |

LxW |

2000x2000 mm |

| Gantry height |

600 mm |

| Workbench |

T-slot width |

28mm |

| Drilling power head |

Qty. |

1 |

| Spindle taper |

BT50-150 |

| Max.drilling diameter |

Φ50 mm |

| Max.thickness |

≤160 mm |

| Tapping diameter |

M3-M28 |

| Spindle speed |

30~3000 r/min |

| Servo spindle motor power |

22kW |

| Distance from the lower end of the spindle to the worktable |

200-600mm |

|

Lateral movement of power head

(X axis)

|

Max.horizontal stroke |

2000 mm |

| Lateral movement speed |

0~8 r/min |

| Servo motor power for lateral movement |

2.4kW |

| Gantry longitudinal movement (Y axis) |

Max. feed stroke |

2000 mm |

| Feed moving speed |

0~8 m/min |

| Feed servo motor power |

2x2.4kW |

| Vertical ram feed motion (Z axis) |

Max. stroke |

400 mm |

| Moving speed |

0~8 m/min |

| Servo motor power |

2.4kW (Brake) |

| Three-axis positioning accuracy |

X/Y/Z/A/B/C |

±0.015/1000mm |

| Three-axis repeat positioning accuracy |

X/Y/Z/A/B/C |

±0.01/1000mm |

| Machine weight |

/ |

About 11.5T |

| Overall size |

LxWxH |

5300x3800x2700 mm |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!