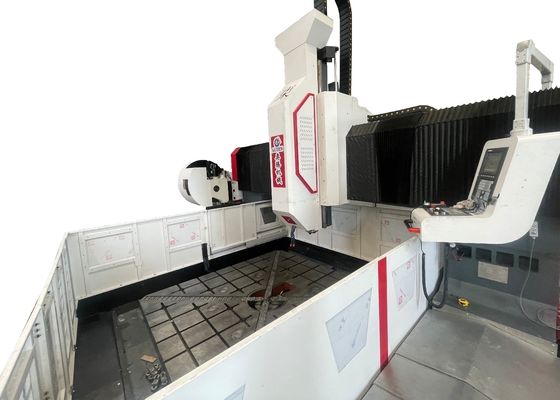

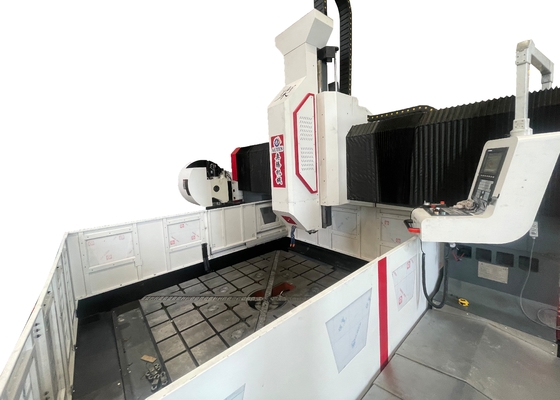

Model PHD2525 Flange Plate CNC Plate Drilling Machine 100mm Max Drilling Diameter

Application:

Employed for drilling, chamfering, tapping, and milling of plates and structural components.

It is primarily dedicated to high-efficiency drilling operations for workpieces including flanges, discs, rings, and plates with thicknesses within the effective processing range. The drilling of through holes and blind holes is achievable on both single-material parts and composite materials. The machining processes of the machine tool are digitally controlled, featuring highly convenient operation, and it is capable of realizing automated, high-precision production with multiple varieties and in mass quantities.

Drilling power head:

The drilling power head adopts a special servo spindle motor, which drives the special precision spindle through the tooth synchronous belt to decelerate and increase the torque. The replacement is quick and easy, and the feed is driven by a servo motor and a ball screw. The X and Y axes can be linked, and the semi-closed loop control is adopted to realize linear and circular interpolation functions. The spindle end is a BT50 taper hole, equipped with a high-speed rotary joint, which can be processed with high-speed U-drill center water.

Transmission device:

Adopting the high-precision design of guide rails and sliders imported from Taiwan, it runs smoothly and effectively improves the heavy load capacity.

a. The X-axis and the Z-axis are respectively in the form of two rolling linear guide rails as the guide and load-bearing rails for lateral and longitudinal movement. It can meet the technical requirements of high-speed drilling. The X-axis Z-axis transmission adopts AC servo motor to drive the precision ball screw to rotate to realize linear motion.

b. There are two heavy-duty rolling linear guide rails on both sides of the Y-axis, and two square rail sliders are installed on each guide rail to form a Y-axis sliding track. It can meet the high rigidity and strength requirements of the gantry frame, and can also meet the technical advantages of small friction coefficient, fast moving speed, good vibration absorption performance and long service life. The X-axis transmission adopts dual-servo motor synchronous drive technology, that is, one servo motor on each side drives the ball screw to rotate synchronously, which drives the gantry frame to move and realizes CNC machining.

Automatic lubricating device and protective device:

This machine tool is equipped with Taiwan original volumetric partial pressure automatic lubricating device, which can automatically lubricate the moving pairs such as guide rails, lead screws, racks, etc., without dead ends, to ensure the service life of the machine tool. The X-axis and Y-axis of the machine tool are equipped with dust-proof shields, and a waterproof splash plate is installed around the worktable.

Central water outlet system:

The machine is equipped with a central water outlet system as standard. The internal water outlet system can prevent the iron pin from wrapping around the tool during processing, reduce tool wear, prolong tool life, and improve the surface finish of the workpiece. Protect the surface of the workpiece, protect the high-speed rotary joint, prevent impurities from blocking the rotary joint, improve the quality of the workpiece as a whole, and improve work efficiency.

Specifications:

| Workpiece size |

LxW |

2500x2500 mm |

| Workbench |

T-slot width |

28mm |

| Drilling power head |

Qty. |

1 |

| Spindle taper |

BT50 |

| Max.drilling diamter |

100 mm

(Carbide core bit)

|

| Φ80 mm (U drill) |

| Max.thickness |

≤180 mm |

| Max.tapping diameter |

M30 mm |

| Spindle speed |

30~3000 r/min |

| Servo spindle motor power |

30kW |

| Distance from the lower end of the spindle to the worktable |

200-600mm |

|

Lateral movement of power head

(X axis)

|

Max.horizontal stroke |

2500 mm |

| Lateral movement speed |

0~8 m/min |

| Servo motor power for lateral movement/torque |

4.5kW/25Nm |

| Gantry longitudinal movement (Y axis) |

Max. feed stroke |

2500 mm |

| Feed moving speed |

0~8 m/min |

| Feed servo motor power/torque |

2x4.5 kW/25Nm |

| Vertical ram feed motion (Z axis) |

Max. stroke |

600 mm |

| Moving speed |

0~5 m/min |

| Servo motor power/torque |

4.5kW/25Nm |

| Three-axis positioning accuracy |

X/Y |

≤0.05mm/1000mm |

| Three-axis repeat positioning accuracy |

X/Y |

≤0.03mm/1000mm |

| Pneumatic system |

Compressed air supply pressure |

≥0.4MPa |

| Chip conveyor and cooling |

Number of chip conveyors |

2 |

| Chip removal speed |

1m/min |

| Chip conveyor motor power |

2X0.75kW |

| Cooling method |

Internal cooling (70bar) + external cooling |

| Automatic lubrication system |

Lubrication pressure |

2MPa |

| Lubrication point oil filling amount |

0.1mL |

| Lubrication cycle |

6-10min |

|

Electrical System

|

CNC system |

Siemens 828D |

| Number of CNC axes |

3 |

| Tool changer |

Disc type |

24 tool positions |

| Overall size |

LxWxH |

6000x4300x2700 mm |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!