35mm Max. Drilling Diameter CNC Metal Milling Machine 200-540mm Distance From Spindle To Worktable

Application:

The CNC plate sheet metal drilling and milling machine is primarily utilized for processing tube sheets, flanges, bearings, heat exchangers, and other products across sectors including petrochemicals, nuclear power, wind power, boilers, and steel structures. It is capable of employing carbide drill bits to conduct high-speed drilling with internal cooling, or adopting high-speed twist drill bits for drilling operations with external cooling. This equipment integrates multiple functional capabilities, such as drilling, chamfering, tapping, milling, and boring. Additionally, it is outfitted with an optional automatic right-angle head, which enables side drilling, side tapping, and side milling processes.

Specifications:

| Workpiece size |

LxW |

600 x 600 mm |

| Gantry height |

400 mm |

| Drilling power head |

Qty. |

1 |

| Spindle taper |

BT40 |

| Max.drilling diamter |

Φ35 mm |

| Max.thickness |

40 mm |

| Tapping diameter |

M3-M15 |

| Spindle speed |

30~3000 r/min |

| Servo spindle motor power |

7.5kW |

| Distance from the lower end of the spindle to the worktable |

200-540mm |

|

Lateral movement of power head (X axis)

|

Max.horizontal stroke |

600 mm |

| Lateral movement speed |

0~9 r/min |

| Servo motor power for lateral movement |

10N/M |

Gantry longitudinal movement (Y axis)

|

Max. feed stroke |

600 mm |

| Feed moving speed |

0~9 m/min |

| Feed servo motor power |

10N/M |

|

Vertical ram feed motion (Z axis)

|

Max. stroke |

400 mm |

| Moving speed |

0~8 m/min |

| Servo motor power |

1x2.4kW (Brake) |

| Three-axis positioning accuracy |

X/Y/Z/A/B/C |

0-0.02mm |

| Three-axis repeat positioning accuracy |

X/Y/Z/A/B/C |

0-0.01mm |

| Overall size |

LxWxH |

2200x1600x2200 mm |

Product features

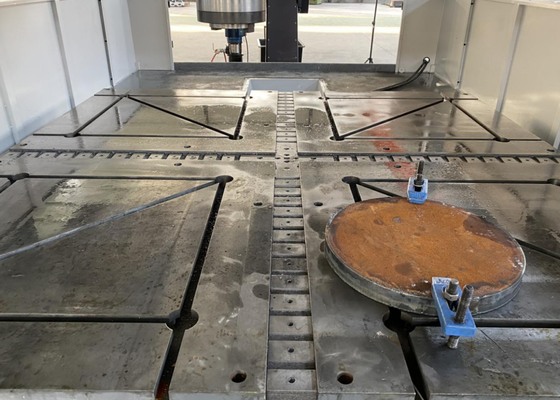

1. There are several horizontal T-slot on the worktable for clamping fixture and plate. Optional four-jaw self-centering chuck clamping device greatly improves the production efficiency of batch parts.

2. Adopt German Siemens CNC system, Spanish FAGOR CNC system or Chinese KND system, drilling coordinates can be directly converted between CAD and CAM, facilitating programming, storage, display, and communication. The user interface features error compensation, automatic alarms, and human-computer interaction. Workpiece hole locations can be input via keyboard, USB, network, or CAD graphics, automatically generating machining programs. Pre-drilling preview and inspection capabilities ensure user-friendly operation.

3. It is equipped with an automatic chip conveyor and an automatic lubrication device. The cooling system is equipped with a high-pressure internal cooling pump and a low-pressure external cooling pump. It can adopt internal cooling or external cooling.

4. It is equipped with a photoelectric edge finder, which can easily and quickly locate the position of the workpiece. Additionally, optional 24T disc tool magazines or linear tool magazines significantly improve machining efficiency.

The CNC gantry-type drilling, marking and milling machine serves as a high-performance industrial device, specifically developed for the precision machining of plate-shaped components and structural parts. This piece of equipment is customized to process workpieces including flanges, discs, rings and flat plates—with a core precondition that the thickness of these workpieces fully conforms to the machine’s specified effective machining range.

Within steel structure workshops, this equipment carries out precision drilling and milling on structural plates and connecting members, thereby establishing a solid basis for the stable assembly of steel frameworks. For the wind power industry, it delivers high-precision machining services for wind turbine towers and flanges—a vital process that ensures these components are capable of withstanding harsh environmental conditions (e.g., strong winds, temperature fluctuations). In bridge construction projects, the equipment processes bridge girders and supporting brackets; this, in turn, secures the formation of stable and long-lasting connections. These connections are engineered to bear dynamic loads throughout the bridge’s prolonged service life.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!