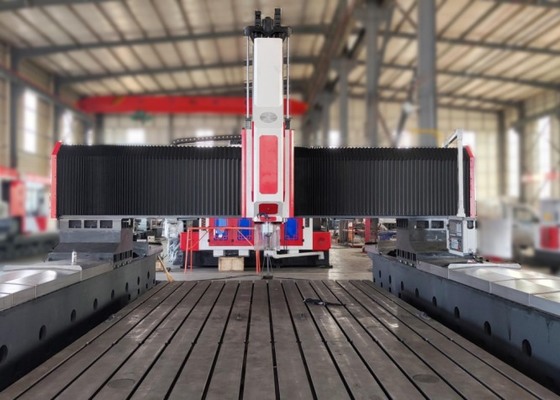

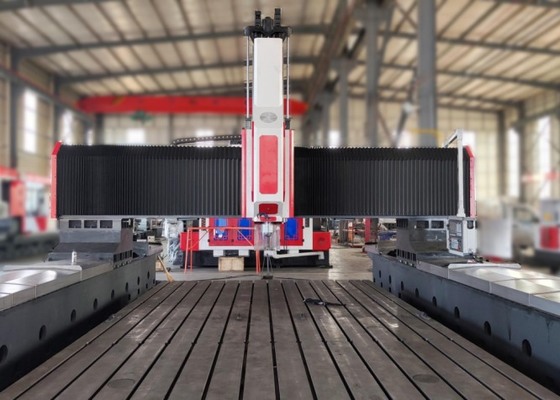

Gantry Mobile Double Spindle CNC Plate Drilling And Milling Machine Model PHD1310

Application:

This CNC gantry-type sheet metal drilling and milling machine is specifically engineered to perform drilling, chamfering, tapping, milling, and boring operations on plate workpieces and structural components. It delivers high-efficiency hole-machining performance for workpieces such as flanges, discs, rings, and plates within its designated thickness range. The equipment is capable of processing through holes and blind holes, and is compatible with both single-material and composite-material components. Furnished with advanced numerical control technology, this machine tool offers superior operational convenience and enables automated, high-precision production of a diverse range of products in large-scale manufacturing settings.

Specifications:

| Workpiece size |

LxW |

13000x1000 mm |

| Gantry height |

600 mm (It can also be determined according to the foundation)

|

| Workbench |

T-slot width |

28mm |

| Drilling power head |

Qty. |

2 |

| Spindle taper |

BT40-150 |

|

Max.drilling diamter

(Ordinary carbon steel)

|

Φ30 mm |

| Tapping diameter |

M3-M10 |

| Spindle speed |

30~6000 r/min |

| Servo spindle motor power |

7.5kW |

| Distance from the lower end of the spindle to the worktable |

200-600mm |

|

Lateral movement of power head (X axis)

|

Max.horizontal stroke |

1000 mm |

| Lateral movement speed |

0~8 r/min |

| Servo motor power for lateral movement |

2.4kW |

|

Gantry longitudinal movement (Y axis)

|

Max. feed stroke |

13000 mm |

| Feed moving speed |

0~8 m/min |

| Feed servo motor power |

2x2.4kW |

| Vertical ram feed motion (Z axis) |

Max. stroke |

300 mm |

| Moving speed |

0~5 m/min |

| Servo motor power |

7.5kW (Brake) |

| Three-axis positioning accuracy |

X/Y/Z/A/B/C |

±0.015/1000mm |

| Three-axis repeat positioning accuracy |

X/Y/Z/A/B/C |

±0.01/1000mm |

| Overall size |

LxWxH |

13000x3000x2500 mm |

Product Features

1. Comprehensive Siemens/KND CNC Control System:

The motor is driven by high-precision absolute-value series servo motors, featuring an RS232 interface and a color display screen with a Chinese-language operating interface, while supporting both on-site and external USB input.

1.1. Integrated with chip breaking functionality, enabling users to set chip breaking time and cycles via the human-machine interface (HMI).

1.2. Equipped with a tool lifting function, allowing the tool lifting height to be configured on the HMI. Upon reaching the preset height during drilling, the drill bit rapidly lifts above the workpiece to expel chips, then swiftly advances back to the drilling surface before automatically resuming operation.

1.3. A centralized operation control cabinet and handheld unit are integrated, operating on a CNC system. The human-machine interface (HMI) incorporates human-machine interaction, error compensation, and automatic alarm functionalities to facilitate convenient programming, storage, display, and communication processes.

1.4. The equipment is equipped with pre-drilling hole position simulation and re-inspection capabilities, significantly enhancing operational convenience.

2. Centralized Water Discharge System:

This machine tool is outfitted with a standard centralized water discharge system. The internal spray-type water discharge mechanism prevents iron filings from adhering to the cutting tool during machining operations, thereby reducing tool wear, extending tool service life, and enhancing the surface finish of workpieces. High-pressure water discharge at the cutting tool tip effectively safeguards the workpiece surface, protects high-speed rotating joints, and prevents impurity-induced clogging of rotating components—ultimately improving overall workpiece quality and boosting operational efficiency.

3. Automatic Chip Conveyor and Circulating Cooling System:

An automatic chip conveyor is installed on each side of the worktable, with a filter fitted at the end. The automatic chip conveyor adopts a flat-chain design, and a cooling pump is mounted on one side. The outlet of the cooling pump is connected to the central water filtration system via a rubber hose. Coolant flows into the chip conveyor, which is then pumped into the central water filtration system by the chip conveyor pump. The filtered coolant is subsequently recirculated to the spindle by a high-pressure cooling pump to provide cooling during drilling operations. A chip transport cart is also included for convenient chip removal.

This high-performance CNC gantry-type plate sheet metal drilling and marking industrial equipment is meticulously engineered for the precision machining of plate-type components and structural parts. Specifically tailored for processing workpieces such as flanges, discs, rings, and flat plates, it has a core requirement that the thickness of these workpieces must strictly comply with the machine’s specified effective machining parameters.

In steel structure workshops, this equipment renders precision drilling and milling operations for structural plates and connecting components, thereby laying a solid foundation for the stable assembly of steel frameworks. Within the wind energy industry, it delivers high-precision machining solutions for wind turbine towers and flanges—an essential process that guarantees these components can endure severe environmental conditions (e.g., strong winds, temperature variations). For bridge construction projects, the equipment processes bridge girders and support brackets, facilitating the formation of stable, durable connections designed to withstand dynamic loads throughout the bridge’s extended service life.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!