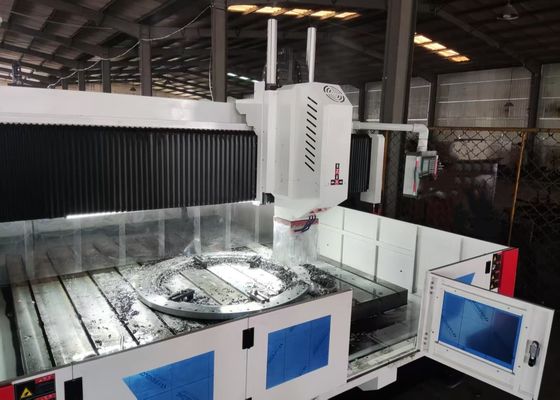

9000x7500x4000mm Overall Size CNC Gantry Flange Drilling Marking Machine BT50 Spindle Taper

Application:

This equipment is primarily engineered to execute drilling, chamfering, tapping, milling, and boring operations on plate and structural components. It delivers high-efficiency hole-drilling performance for workpieces such as flanges, discs, rings, and plates with thicknesses within its specified effective operating range. Boasting the capability to process through holes and blind holes, it demonstrates broad compatibility with both single-material components and composite materials. The machine tool incorporates numerical control for its machining processes, ensuring superior operational convenience. It enables automated, high-precision, multi-variety, and large-scale production capabilities to meet industrial demands.

Specifications:

| Workpiece size |

LxW |

4000x4000 mm |

| Gantry height |

800 mm

(It can also be determined according to the foundation)

|

| Workbench |

T-slot width |

28mm |

| Drilling power head |

Qty. |

1 |

| Spindle taper |

BT50 |

|

Max.drilling diamter

(Ordinary carbon steel)

|

Φ80 mm |

| Max.thickness |

≤150 mm |

| Tapping diameter |

M3-M32 |

| Spindle speed |

30~3000 r/min |

| Servo spindle motor power |

22kW |

| Distance from the lower end of the spindle to the worktable |

200-800mm |

|

Lateral movement of power head (X axis)

|

Max.horizontal stroke |

4000 mm |

| Lateral movement speed |

0~6 r/min |

| Servo motor power for lateral movement |

4.2kW |

|

Gantry longitudinal movement (Y axis)

|

Max. feed stroke |

4000 mm |

| Feed moving speed |

0~6 m/min |

| Feed servo motor power |

2x4.2kW |

| Vertical ram feed motion (Z axis) |

Max. stroke |

500 mm |

| Moving speed |

0~6 m/min |

| Servo motor power |

3.5kW (Brake) |

| Three-axis positioning accuracy |

X/Y/Z/A/B/C |

±0.025/1000mm |

| Three-axis repeat positioning accuracy |

X/Y/Z/A/B/C |

±0.02/1000mm |

| Overall size |

LxWxH |

9000x7500x4000 mm |

| Total power |

About 50 kW |

Equipment Structure:

This equipment is primarily configured with a cast bed workbench, a movable gantry, a mobile saddle, a drilling and milling power head, an automatic lubrication and protection system, a circulating cooling module, a numerical control system, and an electrical control system. Rolling guideways provide stable load-bearing support and precise motion guidance, while precision ball screw transmission mechanisms ensure exceptional positioning accuracy and outstanding repeatability.

Product Features

1. Drilling Power Head:

The drilling power head is outfitted with a dedicated servo spindle motor, which utilizes a toothed synchronous belt for speed reduction and torque enhancement to drive a specialized precision spindle. The spindle adopts a six-row Japanese angular contact bearing arrangement (four at the front, two at the rear) to realize stepless speed regulation. Equipped with a pneumatic tool changing system, the spindle enables rapid and convenient tool replacement. Feed motion is powered by a servo motor paired with a ball screw. The X and Y axes support linkage functionality and employ semi-closed-loop control to achieve linear and circular interpolation capabilities. The spindle nose features a BT50 taper hole and is integrated with a high-speed rotary union, facilitating high-speed U-drill center water-cooled machining operations.

2. Transmission System:

The transmission system adopts Taiwan-sourced guide rails paired with a high-precision slider configuration, ensuring smooth operational traversal and enhanced heavy-load bearing capacity.

3. Automatic Lubrication System and Protection Mechanism:

The machine tool is outfitted with a Taiwan-sourced volumetric pressure-distributing automatic lubrication system. It delivers automatic lubrication to all moving components — including guideways, lead screws, and racks — with full coverage and no gaps, effectively extending the machine tool’s service lifespan. The X-axis and Y-axis of the equipment are fitted with dust-proof protective covers, while water-resistant splash shields are installed around the workbench to ensure operational integrity. .

.

This high-performance CNC gantry industrial machine is specialized in drilling and marking operations for plate and sheet metal components. It is exquisitely engineered to deliver precision machining of plate-type workpieces and structural parts, with dedicated adaptability to processing flanges, discs, rings, flat plates, and similar components. A core prerequisite is that the workpiece thickness must strictly comply with the machine’s pre-set effective machining parameters.

Within steel structure manufacturing facilities, this equipment executes precision drilling and milling on structural plates and connecting elements, laying a robust foundation for the stable assembly of steel frameworks. In the wind energy sector, it delivers high-precision machining solutions for wind turbine towers and flanges — a pivotal process that ensures these components can withstand harsh environmental conditions (e.g., intense winds, temperature variations). For bridge construction projects, the equipment processes bridge girders and support brackets, facilitating the formation of stable, long-lasting connections designed to endure dynamic loads throughout the bridge’s extended service life.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!