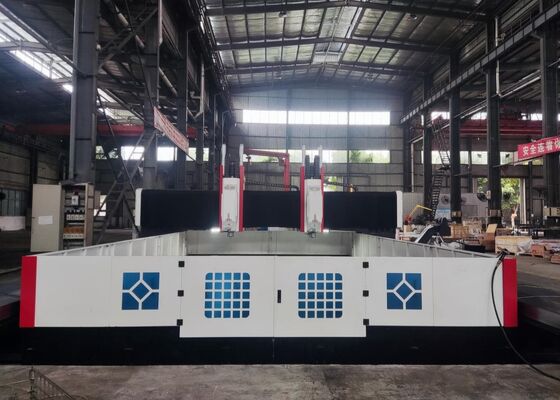

BT50 Spindle Taper Automatic CNC Plate Flange Drilling Machine With PLC Control

Product Introduction:

This CNC gantry drilling machine is primarily used for processing tube sheets, flanges, bearings, heat exchangers, and other components in industries such as petrochemicals, nuclear power, wind energy, boilers, and steel structures. It is capable of high-speed drilling with carbide drill bits featuring internal cooling or using high-speed twist drill bits with external cooling. The machine supports a range of functions, including drilling, chamfering, tapping, milling, and boring. Additionally, it can be equipped with an optional automatic right-angle head for side drilling, tapping, and milling operations.

Product configuration:

| Model |

PHD4080 |

| Workpiece size |

LxW (mm) |

4000x8000 |

| T-slot width of Workbench (mm) |

28 |

| Drilling power head |

Qty. |

1 or 2 |

| Spindle taper |

BT50 |

| Max. drilling diameter (mm) |

Φ90 |

| Max. thickness (mm) |

≤300 |

| Tapping diameter |

M3-M36 |

| Spindle speed (r/min) |

30~3000 |

| Servo spindle motor power (kW) |

22/30/37 |

| Lateral movement of power head (X axis) |

Max. horizontal stroke (mm) |

4000 |

| Lateral movement speed (r/min) |

0~6 |

| Servo motor power for lateral movement (kW) |

3.6 |

| Gantry longitudinal movement (Y axis) |

Max. feed stroke (mm) |

8000 |

| Feed moving speed (m/min) |

0~6 |

| Feed servo motor power (kW) |

3.6/5.5 |

| Vertical ram feed motion (Z axis) |

Max. stroke (mm) |

1400 |

| Moving speed (m/min) |

0~4 |

| Servo motor power (kW) |

3.6 |

| Three-axis positioning accuracy |

X/Y/Z/A/B/C (mm) |

±0.015/1000 |

| Three-axis repeat positioning accuracy |

X/Y/Z/A/B/C (mm) |

±0.01/1000 |

| Electrical system |

CNC system |

SIEMENS/ FAGOR/ KND/ GSK |

| Tool changer |

Disc type (Optional) |

24 tool positions |

| Overall size |

LxWxH (m) |

13x6.9x6.2 |

Product features

1. The flange drilling machine is composed of a bed, longitudinal slide, gantry, transverse slide, vertical feed unit, drilling and milling power head, workbench, cooling system, automatic chip removal system, automatic lubrication system, pneumatic system, electrical system, and other key components.

2. The CNC plate drilling machine features a servo-sliding drilling power head that is capable of drilling, reaming, tapping, chamfering, and groove milling. These functions can operate simultaneously or independently. The drilling spindle is a Taiwan-made precision spindle (internal cooling) with a BT50 taper, and it incorporates a butterfly spring automatic broaching mechanism. The machine can be equipped with either drill bits or milling cutters via a connecting rod and hydraulic cylinder tool release, making tool replacement highly efficient and convenient.

3. The high-speed CNC drilling machine is equipped with high-precision linear guides, ensuring smooth movement. An AC servo motor drives a synchronous belt and precision ball screw pairs, guaranteeing exceptional accuracy.

4. The body and gantry of the CNC drilling machine are constructed from cast materials or high-quality welded steel plates. These components undergo high-temperature annealing before processing, followed by a second annealing after semi-finishing to eliminate residual stresses, ensuring stable and precise performance throughout the machining process.

5. The plate drilling machine is equipped with several horizontal T-slots on the worktable, allowing for the secure clamping of fixtures and plates. An optional four-jaw self-centering chuck clamping device significantly enhances production efficiency for batch processing.

6. The machine utilizes a German Siemens CNC system, a Spanish FAGOR CNC system, or a Chinese KND system. Drilling coordinates can be seamlessly converted between CAD and CAM, streamlining programming, storage, display, and communication. The user interface includes error compensation, automatic alarms, and human-computer interaction features. Workpiece hole locations can be input via keyboard, USB, network, or CAD graphics, with automatic generation of machining programs. Pre-drilling preview and inspection functions further ensure ease of operation.

7. The machine is fitted with a photoelectric edge finder, allowing for quick and accurate workpiece positioning. Additionally, optional 24-tool disc magazines or linear tool magazines greatly enhance machining efficiency.

8. The machine is equipped with an automatic chip conveyor and an automatic lubrication system. The cooling system features both a high-pressure internal cooling pump and a low-pressure external cooling pump, offering the flexibility to use either internal or external cooling.

The CNC gantry plate cutting machine is a durable industrial solution, expertly designed for the precise processing of plate-like components and structural elements. This equipment is specifically optimized for handling workpieces such as flanges, discs, rings, and flat plates, with the condition that the material thickness falls within the machine's defined effective machining range.

In steel structure manufacturing facilities, this plate drilling machine performs precise drilling and milling operations on structural plates and connecting components, providing a reliable foundation for the robust assembly of steel frameworks. In the wind energy industry, it offers high-precision machining for wind turbine towers and flanges—critical processes that ensure these components can endure harsh environmental conditions (such as high winds and temperature variations). For bridge construction projects, the equipment processes bridge girders and supports, ensuring the creation of stable and durable connections capable of withstanding dynamic loads over the bridge's extended service life.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!