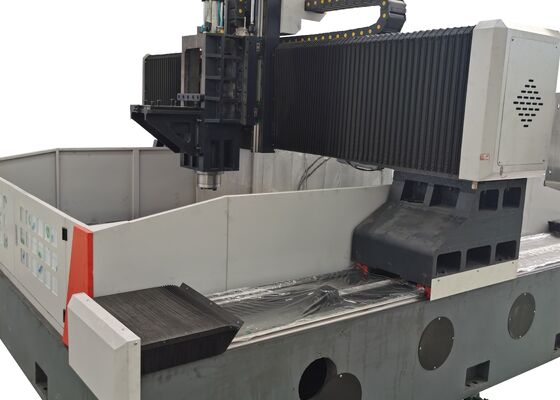

New Designed Cnc Gantry Type Plate Steel Sheet Flange Drilling Machine M3-28 Tapping Diameter

Product Introduction

The CNC gantry-type drilling and milling machine is specifically designed for performing drilling, chamfering, tapping, and milling operations on plate workpieces and structural components. Its processing capabilities extend to workpieces such as flanges, discs, rings, and flat plates, with thickness parameters strictly adhering to the machine’s specified effective processing range. The machine supports the machining of both through holes and blind holes on single-material and composite material components. Featuring full digital control throughout the machining process, it ensures exceptional ease of operation and efficiency. The machine is ideally suited for automated production, delivering high-precision results and meeting the demands of multi-variety and large-scale manufacturing environments.

Specifications:

| Workpiece size |

LxW |

1200x1200 mm |

| Gantry height |

750 mm |

| Workbench |

T-slot width |

18mm |

| Drilling power head |

Qty. |

1 |

| Spindle taper |

BT50 |

|

Max.drilling diameter

(Ordinary carbon steel)

|

Φ60 mm |

| Tapping diameter |

M3-M28 |

| Spindle speed |

30~3000 r/min |

| Servo spindle motor power |

22kW |

| Distance from the lower end of the spindle to the worktable |

200-750mm |

|

Lateral movement of power head (X axis)

|

Max.horizontal stroke |

1200 mm |

| Lateral movement speed |

0~8 r/min |

| Servo motor power for lateral movement |

2.4kW |

| Gantry longitudinal movement (Y axis) |

Max. feed stroke |

1200 mm |

| Feed moving speed |

0~8 m/min |

| Feed servo motor power |

2.4kW |

| Vertical ram feed motion (Z axis) |

Max. stroke |

550 mm |

| Moving speed |

0~8 m/min |

| Servo motor power |

2.8kW (Brake) |

| Three-axis positioning accuracy |

X/Y/Z/A/B/C |

±0.015/1000mm |

| Three-axis repeat positioning accuracy |

X/Y/Z/A/B/C |

±0.01/1000mm |

| Overall size |

LxWxH |

4000x3800x2800 mm |

Product Features

1. Transmission System:

The high-precision guide rails and sliders, imported from Taiwan, are engineered to deliver smooth operational performance while substantially enhancing the equipment’s heavy-load capacity.

The X-axis and Z-axis are equipped with two and four rolling linear guides, respectively, serving as the guiding and load-bearing elements for lateral and longitudinal movement. This arrangement fully satisfies the technical requirements for high-speed drilling operations. For power transmission, the X-axis and Z-axis utilize AC servo motors to drive precision ball screws, converting rotational motion into accurate linear displacement.

The Y-axis is equipped with two heavy-duty rolling linear guides, each featuring two square rail sliders to form the Y-axis sliding mechanism. This design not only satisfies the high rigidity and strength requirements of the gantry frame but also offers several technical advantages, including a low friction coefficient, high movement speed, excellent vibration damping, and an extended service life. For power transmission, the Y-axis utilizes servo motor synchronous drive technology, which drives the ball screws in unison, thereby enabling the reciprocating motion of the Y-axis workbench to achieve precise CNC machining operations.

2. Automatic Lubrication System and Protective Mechanisms:

This machine tool is equipped with a Taiwan-made volumetric partial-pressure automatic lubrication system, ensuring thorough, angle-free lubrication for moving components such as guide rails, lead screws, and racks, thereby effectively prolonging the machine tool’s service life. The X-axis and Y-axis are fitted with dustproof protective covers, while waterproof splash guards are installed around the workbench to provide enhanced protection during operation.

3. Central Coolant Delivery System:

This machine tool is equipped with a standard central coolant delivery system. The internal coolant circulation effectively prevents iron chips from adhering to the tool during machining, reducing tool wear, extending tool life, and improving the surface finish of workpieces. The high-pressure coolant outlet at the tool tip ensures reliable protection for both the workpiece surface and the high-speed rotary joint, preventing clogging due to impurities and enhancing overall workpiece quality and operational efficiency.

This high-performance CNC gantry-type industrial equipment, designed for plate and sheet metal drilling and marking applications, is meticulously crafted for the precise machining of plate-like components and structural parts. Specifically optimized for processing workpieces such as flanges, discs, rings, and flat plates, it adheres to a key specification that the thickness of these workpieces must strictly conform to the machine’s pre-set effective machining parameters.

In steel structure manufacturing plants, this equipment performs precise drilling and milling operations on structural plates and connecting components, providing a solid foundation for the stable assembly of steel frameworks. In the wind energy sector, it offers high-precision machining solutions for wind turbine towers and flanges—an essential process that ensures these components can endure harsh environmental conditions (e.g., high winds, temperature fluctuations). For bridge construction projects, the equipment processes bridge girders and support brackets, enabling the creation of stable and durable connections designed to withstand dynamic loads over the bridge’s long operational life.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!