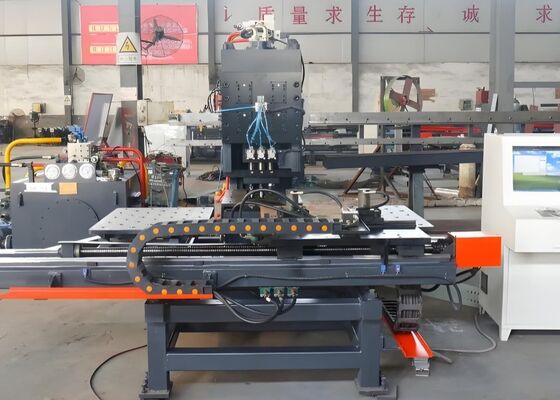

1. The CNC channel steel punching and marking machine is constructed with a robust C-type welded frame, guaranteeing superior structural stability and providing ample operational space. It is equipped with three die stations, one of which is solely designated for marking, and features automatic indexing between stations to optimize workflow efficiency. The clamping system is highly adaptable, accommodating a wide variety of workpieces, with a zero-reference baffle ensuring precise alignment. Workpieces are securely positioned on a ball-bearing worktable, enabling smooth and effortless handling. Movement along both the X and Y axes is powered by servo motors, with high-precision ball screws ensuring accurate transmission, while punching position accuracy is managed by a Programmable Logic Controller (PLC), enabling full automation of the machining process. Additionally, the system supports the storage, retrieval, and reuse of workpiece programs, ensuring uninterrupted batch production cycles.

2. The CNC steel drilling machine utilizes cutting-edge Computer Numerical Control (CNC) technology, combined with servo motor-driven feed systems, ensuring exceptional operational efficiency and consistent precision across a diverse range of workpieces.

3. The machine’s critical functional components are engineered with a modular design, enhancing ease of maintenance and streamlining repair procedures.

4. The CNC metal plate punching and marking machine seamlessly combines punching, marking, and drilling functions into a unified process, delivering versatile capabilities within a single, integrated operational cycle.

5. The drilling module is equipped with essential features such as rapid downward feed, precise machining progression, and quick retraction, significantly improving operational efficiency in real-world work environments.

6. Featuring an advanced self-diagnostic fault detection system, the machine promptly detects any operational issues, facilitating timely maintenance and ensuring uninterrupted production reliability.

7. The programming interface is designed for ease of use: operators can directly enter hole diameters, positional coordinates, and batch quantities into the control system. Additionally, the system is fully compatible with programs generated by specialized lofting software and supports the seamless conversion of CAD/CAM files, ensuring efficient and uninterrupted program execution.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!