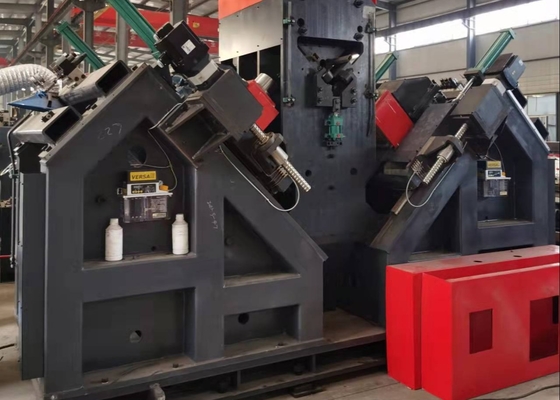

About 150KW Total power CNC Angle Drilling And Marking Line 9 CNC axes Hydraulic station air cooling method

Product Usage:

This equipment is primarily intended for drilling and stamping large-size, high-strength angle steel utilized in transmission line towers. All holes required on the angle steel can be machined on this production line, characterized by superior hole quality, precise positional accuracy, as well as high production efficiency and automation levels.

High positional accuracy in hole making. The feeding device of this production line is driven by a servo motor via a gear and rack mechanism, and is equipped with a detection rack, detection gear, and a detection encoder for positional accuracy feedback, forming a full closed-loop control system. The movement of the drilling power head along the directions of the two flanks of the angle steel is driven by a servo motor through a ball screw, ensuring high positional accuracy of the holes on angle steel workpieces.

High drilling efficiency and superior hole-making quality. The drilling unit is equipped with six sets of CNC drilling heads, with three sets allocated to each of the two flanges of the angle steel. Holes of the same diameter and with the same end distance on both flanges can be drilled simultaneously by the corresponding drilling heads on each side. The drilling spindle employs a Taiwanese BT40 precision spindle (with internal cooling), and the drilling head utilizes a cemented carbide drill bit. The cutting speed of the drill bit reaches up to 200 m/min (compared to 25-35 m/min for conventional high-speed steel twist drills), enabling rapid operation. The servo motor drives the CNC drilling power head for feeding, with the drill's rapid traverse, working feed, and rapid retraction controlled by the CNC system and completed automatically. The retraction position of the drill can be preset in the host computer, reducing idle strokes and further enhancing production efficiency. The tolerance of the drilled hole diameter is less than 0.1 mm, and the surface finish of the hole (Ra) is less than 6.3 μm, ensuring high hole-processing quality.

(1)The spindle motor of the drilling unit adopts a high-quality inverter motor, with a maximum spindle speed of up to 6000 r/min.

(2)The drill pipe feeding speed is approximately 40 m/min (adjustable).

(3)Stressed components such as the spindle undergo forging, heat treatment, and non-destructive testing in accordance with standards, ensuring sufficient strength, hardness, wear resistance, and high fatigue strength to meet the requirements of long-term feeding and rotational operations. The spindle is sourced from Taiwanese brands such as Jianchun or Danquan.

(4)To ensure the operational accuracy of the equipment, the spindle deflection must be less than 1/1000 of the span under all maximum load conditions.

(5)The spindle feeding distance features an adjustable compensation function.

(6)Travel switches are installed at the upper and lower limit positions of the collinear movement of the drilling unit's power head to serve as limit protection.

(7)In addition to the limit switch protection installed on the unit power head, the control system is also equipped with soft limit protection for its limit positions.

Main parameters:

| Model |

ADM2532 |

| Angle size(mm) |

140*140*10~250*250*32 |

| Max. length of raw material (m) |

14 |

| Marking force(kN) |

1000 |

| No. of character group |

1 |

| No. of character |

18 |

| Character size (mm) |

14*10*19 |

| Range of accurate distance(mm) |

50~220(Stepless) |

| No. of drill on each side |

3(2 groups, 6 in total) |

| No. of blade on each side |

3 |

|

Taper of drilling spindle

|

BT40 |

| Max. drilling diameter (mm) |

Φ40 |

| Max. Spindle rotation speed(r/min) |

6000 |

| Drill cooling unit |

MQL 360-2(Dry cooling) |

| Cooling unit oil storage capacity |

2L |

| Cutting oil |

Vegetable oil-based micro cutting oils(2000-25) |

| fuel consumption |

5~50ml/h |

| CNC trolley drive type |

AC servo motor,rack and pinion driving |

| Max. feeding speed of angle(m/min) |

40 |

| AB-axis alignment movement drive method |

Linear Motion Guide;AC servo motor;Ball screw Secondary driving |

| Max. skateboard travel speed of drilling head(m/min) |

10 |

| Drilling head drive type |

Linear Motion Guide;AC servo motor;Ball screw Secondary driving |

| Max. feeding speed of drilling head(m/min) |

14 |

| Feeder trolley arm working method |

Vertical lifting type |

| Number of tipping cylinders on discharge side |

4 |

| Hydraulic station cooling method |

Air cooling |

| No. of CNC axes |

9 |

| Air pressure(MPa) |

1 |

| Total power |

About 150KW |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!