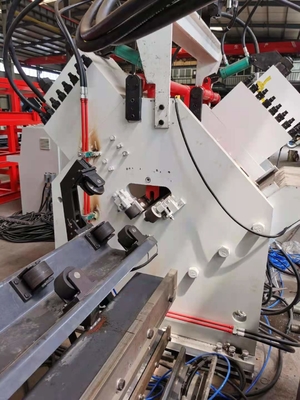

Steel Flange CNC Angle Line Machine With Punching Marking Function

CNC Angle Line Machine includes 5 parts: feeding device, host part, cutting device, hydraulic and electrical system. PLC control system ensures accuracy, high efficiency, and lower labor cost.

Special advantages:

1. Space between our character groups is larger which can accommodates bigger size characters.

2. Enclosed marking unit. It is more stable, safe and prolongs the marking unit life.

3. Machine suitable to Indian condition like motor of 415 volts, 50 Hz.

4. All main cable, such as rotary encoder cable, PLC communication cable is shielding twisted-pair cable imported. Thus, it avoids accuracy error caused by signal interference.

5. Double accumulators to improve the punching speed.

6. Denison pump for hydraulic motor, better quality and lower noisy.

Product Feature:

1. Feeding speed and punching speed are very fast. The speed is 3 times higher than previous common angle line machines. Greatly improve the production efficiency.

2. There are two sets of punching die-station on each side which can be installed two kinds of punches with different diameters.

3. Marking unit adopts closed frame with good rigidity. Four sets of character boxes are fixed on the marking unit which can be selected by program. Marking stadia can be set at will.

Adopt CNC technology, servo motor in feeding, with high efficiency, stable work piece precision. Key hydraulic, pneumatic and electric parts all imported.

4. Hydraulic system mainly serves for punching, cutting, marking, pressing and transposition of character boxes. All marking, punching and shearing in automatic completeness, all finished angles can be unloaded by pneumatic turnover device so as to lighten the working strength.

Specifications:

| Model |

APM2020 |

| Functions |

Punching, marking, cutting |

| Angle size(mm) |

∟63×63×4~∟200×200×20 |

| Max. length of blank (m) |

14 |

| Max. length of finished (m) |

14 |

| Max. Punching (dia. х thi.) (mm) |

Φ26×20(Material:Q345 510N/mm2) |

| Punches per side |

3 |

| Punching force (kN) |

1000 |

| Marking force (kN) |

1200 |

| Cutting force (kN) |

4300 |

| Group of Marking letters |

4 |

| Number of letters per group |

12 |

| Dimension of letter (mm) |

14×10×19 |

| Cutting mode |

Single blade cutting |

| Max. Cutting capacity |

∟63×63×4~∟200×200×20 |

| (Material:Q345 510N/mm2) |

| CNC axes |

3 |

| Feeding speed of angle (m/min) |

60 |

| Cooling method of hydraulic system |

Water cooling |

| Processing precision |

Accordance with GB2694 |

| Program function |

Input by keyboard and USB interface |

| Dimension(mm) |

32000×6500×2350 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!