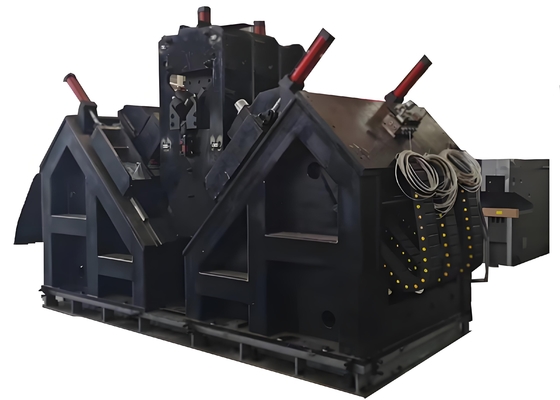

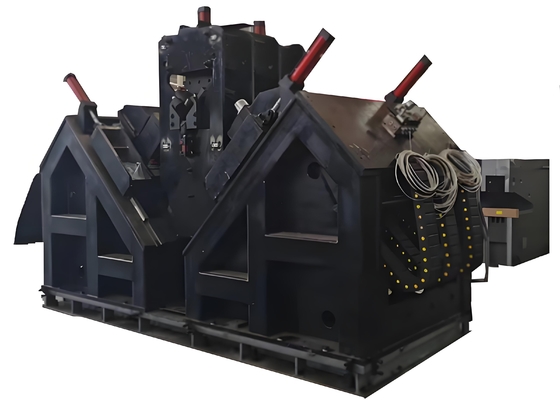

3 Drills On Each Side CNC Angle Drilling And Tapping Machine Line 40m/Min Feeding Speed Of Angle

Product Usage:

This production line is specifically designed for drilling and stamping large-size, high-strength angle steel applied in transmission line towers. All required holes on the angle steel can be processed on this line, boasting excellent hole quality, high positional accuracy, as well as high production efficiency and advanced automation capabilities.

Main parameters:

| Model |

ADM2532 |

| Angle size(mm) |

140*140*10~250*250*32 |

| Max. length of raw material (m) |

14 |

| Marking force(kN) |

1000 |

| No. of character group |

1 |

| No. of character |

18 |

| Character size (mm) |

14*10*19 |

| Range of accurate distance(mm) |

50~220(Stepless) |

| No. of drill on each side |

3(2 groups, 6 in total) |

| No. of blade on each side |

3 |

|

Taper of drilling spindle

|

BT40 |

| Max. drilling diameter (mm) |

Φ40 |

| Max. Spindle rotation speed(r/min) |

6000 |

| Drill cooling unit |

MQL 360-2(Dry cooling) |

| Cooling unit oil storage capacity |

2L |

| Cutting oil |

Vegetable oil-based micro cutting oils(2000-25) |

| fuel consumption |

5~50ml/h |

| CNC trolley drive type |

AC servo motor,rack and pinion driving |

| Max. feeding speed of angle(m/min) |

40 |

| AB-axis alignment movement drive method |

Linear Motion Guide;AC servo motor;Ball screw Secondary driving |

| Max. skateboard travel speed of drilling head(m/min) |

10 |

| Drilling head drive type |

Linear Motion Guide;AC servo motor;Ball screw Secondary driving |

| Max. feeding speed of drilling head(m/min) |

14 |

| Feeder trolley arm working method |

Vertical lifting type |

| Number of tipping cylinders on discharge side |

4 |

| Hydraulic station cooling method |

Air cooling |

| No. of CNC axes |

9 |

| Air pressure(MPa) |

1 |

| Total power |

About 150KW |

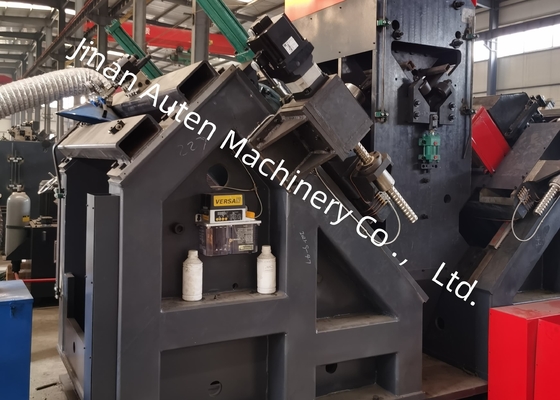

Product Features:

1. The drilling spindle is equipped with a disc spring automatic tool clamping mechanism and a hydraulic cylinder for tool release, which enables convenient replacement of tool shanks. The front section of the spindle adopts a labyrinth seal protection structure and a waterproof design, and is fitted with an air curtain device—this configuration effectively prevents cutting fluid from entering the interior of the spindle..

2. The production line is outfitted with an automatic loading device (comprising a transverse feeding channel and a rotating loading rack), an automatic unloading device, and an automatic feeding device. All holes and steel identification markings required on the angle steel can be completed in a single pass through the production line, with no manual intervention needed during the processing process. This not only streamlines the workflow but also significantly reduces the labor intensity of operators.

3. The marking unit adopts a closed-body structure, featuring high structural strength and stable operation performance. It is configured with a bed support (fixed to the machine base), a movable bed, and a hydraulic-driven press-head character box. In accordance with computer instructions, marking operations are executed at the positions specified in the engineering drawings. To expand the machine’s processing range, a manual adjustment mechanism has been additionally integrated. This mechanism allows for adjustments to the downward position of the movable bed (i.e., the position of the character head), enabling adaptation to the marking positions of angle steel with different specifications.

These specimens cover a variety of common specifications and hole layouts of angle steel applied in transmission line towers. They allow potential users or inspectors to visually verify the equipment’s operational performance, thereby providing tangible and intuitive references for assessing whether the equipment meets the practical demands of production.

This equipment is specifically engineered for drilling and stamping large-size, high-strength angle steel utilized in transmission line towers, and is widely applied across diverse scenarios throughout the construction and maintenance of power transmission infrastructure. In the construction of ultra-high voltage (UHV) transmission lines—where towers are required to withstand extreme weather conditions and heavy loads—this equipment assumes a critical role in processing the angle steel components that constitute the main framework of the towers. It efficiently fulfills the drilling and stamping tasks for angle steel used in tower bodies, cross-arms, and other key structural parts, guaranteeing precise dimensional accuracy and robust connections to secure the overall stability of the towers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!