New CNC H Beam Drilling Machine For Steel Construction 11/15KW Spindle Motor Power

Product Introduction:

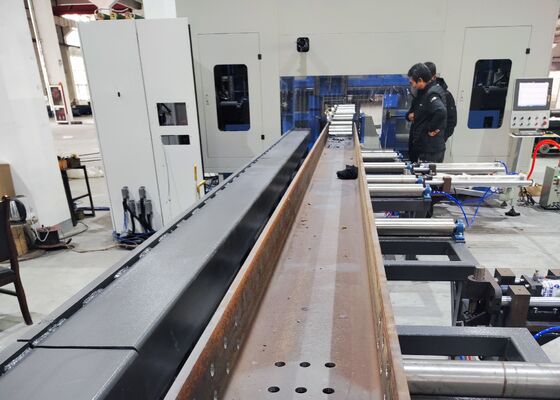

The CNC H-beam drilling machine is primarily designed for drilling, tapping, marking, and scoring H-shaped steel, channel steel, angle steel, and other metal materials. It is widely used in the steel structure industry, including applications in buildings, garages, towers, and grid structures.

1. A vital and specialized drilling solution for steel structure construction.

2. Capable of drilling holes on three surfaces of H-beams and channels simultaneously, ensuring high precision and efficiency.

3. Equipped with 7 CNC axes, enabling fully automated, precise feeding and positioning.

4. Compatible with AUTOCAD and DSTV workpiece drawings, effortlessly converting them into machining programs.

Product parameters:

| Model |

BHD1000/3 |

| H Beam width range (mm) |

100~1000 |

| H Beam height range (mm) |

100~500 |

| Channel steel width range (mm) |

100~1000 |

| Channel steel height range (mm) |

100~250 |

| Max. workpiece thickness (mm) |

80 |

| Max. workpiece length (m) |

12 or 15 (optional) |

| Drilling spindle qty. |

Total 3 spindles, one spindle on the upper unit, left side and right side respectively |

| Spindle hole taper |

BT40 |

| Max.drilling diameter (mm) |

40 |

| Spindle motor power (kW) |

11/15 |

| Spindle speed (r/min) |

100~3000 |

| Spindle feeding speed (m/min) |

0~10 |

| X-axis feeding speed (m/min) |

0~20 |

| Qty of tool magazine |

3 |

| Tool magazine type and capacity |

Row type, 3x4 (optional) |

| Marking unit (optional) |

Disc typing, 36 characters, character size Φ10mm |

| CNC system |

German Siemens, Japan Panasonic, China INVT |

| Cooling method |

Spray cooling, internal cooling + external cooling |

| Machine Overall Size (m) |

About 33x5.5x3.5 |

| Total Power(kW) |

About 60 |

| The above parameters can be adjusted and changed according to customer's specific requirements. |

Product Features:

1. The feeding mechanism of the beam saw machine incorporates a CNC-controlled carriage clamping and feeding system, guaranteeing high-speed operation and precise positioning accuracy.

2. Three BT40 high-speed spindles are utilized to drill the three surfaces of the H-beam. Equipped with carbide drill bits, the spindles can achieve rotational speeds of up to 3000 RPM, ensuring superior processing efficiency and outstanding drilling performance. The chips generated during drilling are effectively removed by the chain-type chip conveyor.

3. The CNC beam drill line cooling system employs mist cooling technology, providing both internal and external cooling capabilities. Each drilling spindle unit is equipped with a dedicated external cooling nozzle and an internal cooling connector, offering flexibility to choose the appropriate cooling method based on the specific drilling requirements. Internal and external cooling can be used independently or simultaneously, depending on operational needs.

4. The automatic tool changer (ATC) system can be installed according to customer specifications, eliminating the need for manual tool changes. This feature significantly reduces downtime and improves overall operational efficiency.

5. The beam drilling machine can be optionally equipped with a hydraulic disc marking system. The disc is precisely positioned by a servo motor, enabling the rapid marking of up to 36 different characters.

6. The automatic scribing and tapping functions replace traditional manual scribing processes. Scribing tools are used to mark the plate positions for subsequent welding on H-beam flanges and webs, saving time and improving accuracy. Additionally, tapping operations can be performed on the H-beam flanges and webs, significantly increasing production efficiency.

7. The workpiece clamping process during feeding and processing on the CNC beam drilling machine—comprising longitudinal lifting, lateral push clamping, and the securing and releasing of clamps—is fully automated by the hydraulic system. This ensures the reliable and consistent operation of the equipment throughout the entire process.

8. The control system consists of a central computer and a PLC, with key components sourced from well-known international brands. The system supports multiple programming methods, allowing operators to easily edit various programs. Structural design data, such as DXF and DSTV files generated by third-party AutoCAD or TEKLA Structures systems, can be seamlessly imported.

During sample demonstration sessions, the CNC beam plate metal drilling, marking, and shearing machine effectively showcases its processing capabilities using standard H-beam samples (with varying flange widths and web thicknesses) as well as channel steel samples of different sizes. The samples displayed in these demonstrations clearly highlight the machine's ability to achieve precise hole positioning, cleanly tapped threads, and distinct marking patterns—thoroughly demonstrating its high precision and dependability in practical application scenarios.

The High-Speed CNC H-Beam Drilling, Marking, and Shearing Machine is primarily utilized in steel structure fabrication plants and bridge construction projects. In steel structure workshops, it performs precise processing on H-beams used in frameworks and support systems, providing a solid foundation for the stable assembly of steel structures. In bridge construction, the machine conducts high-precision drilling operations on H-beams, thereby enhancing the structural integrity of bridges and ensuring their capacity to bear long-term loads. With its exceptional operational efficiency, the machine offers dependable support to these critical infrastructure sectors, driving the smooth advancement of related projects.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!