2200/4300KN Cutting Force CNC Angle Punching Shearing Steel Tower Production Line 18 Letters Per Group

Product Introduction:

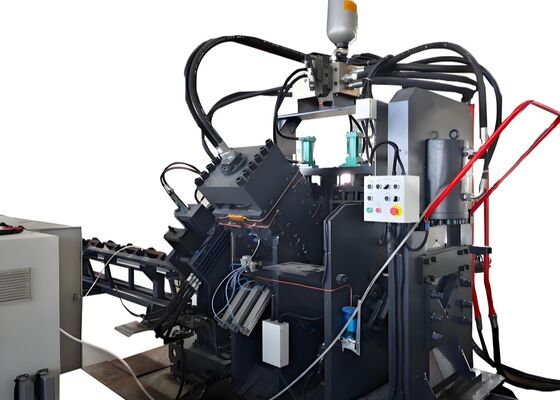

The JNC series high-speed CNC angle punching, marking, and cutting production line consists primarily of the punching unit, marking unit, cutting unit, transverse conveyor, rotating conveyor, feeding conveyor, unloading conveyor, CNC feeding carriage, hydraulic system, electrical system, pneumatic system, and other critical components. Designed specifically for the automated processing of angle steel in the tower manufacturing sector, this production line operates under full numerical control, ensuring ease of use. It enables automated, high-precision, multi-variety, and large-scale production capabilities.

Product parameters:

| Model |

JNC2020 |

| Angle size (mm) |

50х50х4~200х200х20 |

| Max. Punching (Dia. х Thi.) (mm) |

Φ26х20 |

| Punching force (kN) |

1000/1200 |

| Marking force (kN) |

1000/1200 |

| Cutting force (kN) |

2200/4300 |

| Max. length of blank (m) |

14 |

| Max. length of finished (m) |

12 |

| Punches per side |

3 |

| Group of marking letters |

4 |

| Number of letters per group |

18 |

| Character size(mm) |

14x10x19 |

| CNC axes |

3 |

| Cutting mode |

Double Blade or Single Blade |

| Cooling method |

Water cooling/Air cooling/Oil chiller |

| Max. feeding speed (m/min) |

80 |

| Programming mode |

Lofting software or instruction programming |

| Overall dimension (m) |

About 32x7x3 |

| The above parameters can be adjusted and changed according to customer's specific requirements. |

Product Features:

1. The CNC angle iron punching machine is equipped with either two or three punching units, each capable of accommodating three different punch sizes. These punching units are precisely controlled by numerical control (NC), ensuring accurate adjustments to punching positions. The machine can produce both round and oval holes. With high-speed feeding and punching capabilities, it greatly improves production efficiency. For 50×50×4mm angle steel, the machine achieves a production capacity of 9-10 tons during an eight-hour shift.

2. The marking unit of the CNC angle punching machine is housed in a robust and durable enclosure. The marking system features four cassette sets, which can be selected through programming, offering flexibility in adjusting the marking position. Furthermore, the machine utilizes a disc marking method with 10 rows, automatically selecting characters without the need for manual input, thus significantly enhancing marking efficiency.

3. The CNC angle bar cutting machine features a single-blade shearing unit, known for its exceptional cutting force. Each cut is performed with zero material waste, delivering a clean and smooth cutting surface. The blade housing is designed with an open-door structure, allowing for quick and safe blade replacements.

4. The horizontal material table efficiently transfers the angle bar to the rotating material rack, which is driven by a motor and reducer. This system ensures secure positioning of the angle bar onto the feeding conveyor for subsequent processing.

5. The workpiece is securely held and fed by a CNC feeding carriage, guaranteeing precise alignment and positioning accuracy. The feeding carriage is driven by a servo motor, with feedback from a photoelectric encoder, operating within a closed-loop control system.

6. The CNC angle steel metal punching and marking machine operates through a hydraulic system that drives the punching, marking, and shearing functions. It is equipped with a high-speed hydraulic station featuring an accumulator, and the hydraulic lines employ ferrule-type connections, ensuring leak-proof operation and simplifying replacement and maintenance. The main hydraulic valve blocks are sourced from the renowned Atos brand, guaranteeing a reliable and high-performance hydraulic system.

7. The hydraulic station’s cooling system offers various options, including water cooling, air cooling, or oil chilling. This flexibility enables customers to choose the most appropriate cooling method based on their specific operational needs.

8. The control system comprises an upper computer, PLC, servo motor, external detection switches, and other essential components. The operator simply inputs the processing requirements, and the system automatically generates the corresponding processing program. It is also compatible with file formats such as DXF, NC, and others generated by CAD software. The upper computer’s human-machine interface is highly intuitive, offering a user-friendly display and simplified operation. It supports features such as graphical workpiece visualization, extensive data storage, location data tracking, and fault alarm notifications.

These samples, reflecting standard specifications and typical processing conditions within the angle steel tower industry, enable users to directly evaluate the equipment's processing quality, accuracy, and craftsmanship. They provide a tangible benchmark for assessing the equipment's performance and its suitability for specific production needs, thereby facilitating informed, data-driven decision-making for potential applications.

In the construction of ultra-high voltage (UHV) transmission lines, where towers are subjected to severe weather conditions and significant loads, this equipment is essential for processing the angle steel components that form the primary structural framework of the towers. It effectively carries out drilling and stamping operations on the angle steel used for tower bodies, cross-arms, and other critical structural elements, ensuring precise dimensions and secure connections that maintain the overall stability and integrity of the towers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!