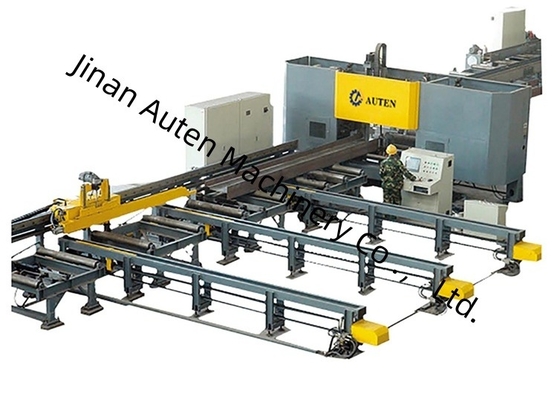

Three-Spindle BT40 CNC Beam Drilling Marking And Shearing Machine Beam Length 2000~13000mm

Machine tool use:

This machine tool is mainly used for drilling, tapping and marking H-shaped steel, channel steel and other steel. Three BT40 high-speed spindles are used to drill three faces of the steel. Each face has one spindle, and the corresponding row tool magazine can accommodate up to 4 specifications of drill bits.

It has the characteristics of high processing efficiency, high precision, easy operation and wide applicability. It is widely used in steel structure industries such as construction, garages, towers and grids.

Machine tool structure and configuration:

This machine tool mainly consists of drilling machine, feeding trolley, feeding channel, discharging channel, cooling system, hydraulic system, pneumatic system, lubrication system, electrical system, etc. The machine tool adopts a fixed bed and movable workpiece structure. This structure of three-dimensional drilling is convenient for automated production.

Drilling machine

The drilling machine mainly consists of a base, a bed, a movable slide, a spindle box, an upper pressing device, a side clamping device and a row tool magazine.

The machine tool has three spindle boxes, namely the fixed side, the movable side and the upper unit spindle box, which are used for drilling in the horizontal and vertical directions respectively. Each spindle box can be operated independently and can complete the drilling operation at the same time, which greatly improves the production efficiency. Each spindle box has a set of BT40 high-speed mechanical spindles, and the corresponding row tool magazine can be installed with a maximum of 4 diameters of drill bits (when there is no tool on the spindle), and 4 different hole diameters can be automatically processed when the workpiece is clamped once. The spindle feed is driven by a servo motor, and fast forward, working forward and fast backward can be achieved through program control; the spindle motor is driven by a spindle servo motor, and the speed is steplessly adjusted with a wide speed regulation range.

The three spindle box units are hung on the bed side, and each spindle box unit is driven by two sets of servo motors to achieve horizontal and vertical movement of the spindle box, which is driven by ball screws and guided by precision linear rolling guides. This equipment presses the workpiece in two directions during the drilling process. A hydraulic cylinder drives a pressing mechanism above the workpiece to press the workpiece against the horizontal support roller, and a hydraulic cylinder drives a pressing mechanism on the side to press the workpiece from the side.

Specifications:

| H beam parameter |

Max. Size Width x Height |

500×500mm |

| Min. Size Width x Height |

100×100mm |

| Beam Length |

2000~13000mm |

| |

Channel steel |

10#~40# |

| Main spindle |

Qty. |

3 |

| Model |

BT40 |

| Motor power |

11 kW |

| Spindle speed |

100~3000 r/min |

| Hole diameter |

φ5~φ30 mm |

| CNC axis |

Servo motor power of X axis |

About 4.5 kW |

| Servo motor power of horizontal drilling positioning axis |

About 1.5 kW |

| Servo motor power of vertical drilling positioning axis |

About 3 kW |

| Servo motor of drilling infeeding |

About 2 kW |

| Tool magazine |

Qty. |

3 |

| Type |

Row style |

| Tool magazine capacity |

4 x 3 |

| Processing Accuracy |

Hole distance deviation |

Two holes within 1 meter |

±0.5 |

| The allowable deviation value increases by ±0.2mm for every additional 1 meter of the hole distance, and the maximum does not exceed ±2mm |

| End margin deviation |

±1.0 mm |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!